Components of natural gas

At the point of extraction, natural gas comprises 20 or more individual hydrocarbon and non-hydrocarbon components. Methane is the main component, normally between 60 and 90%, with other components present in different proportions, from high percentages to traces of less than 0.01%. Unwanted non-hydrocarbon components include carbon dioxide, hydrogen sulphide and moisture. In addition to methane, other hydrocarbon components are ethane (C2H6), propane (C3H8) and butane (C4H10).

The initial processing dries the gas to eliminate liquid water and reduce the concentration of water vapour. Subsequent processing eliminates CO2 and H2S before the reduced-temperature separation extracts the entrained condensates and reduces the concentration of non-methane hydrocarbons, such as natural gas liquids (NGLs): ethane, propane, butane, isobutane and natural gasoline. The result is a mixture of gases with a high proportion of methane, but which still contains varying amounts of ethane, propane and butane.

Therefore, the term ‘natural gas’ describes a mixture of gases containing a wide range of hydrocarbons, from short-chain light aliphatics (non-aromatic compounds) to long-chain heavy molecules.

How does the industry define the dew point of hydrocarbons?

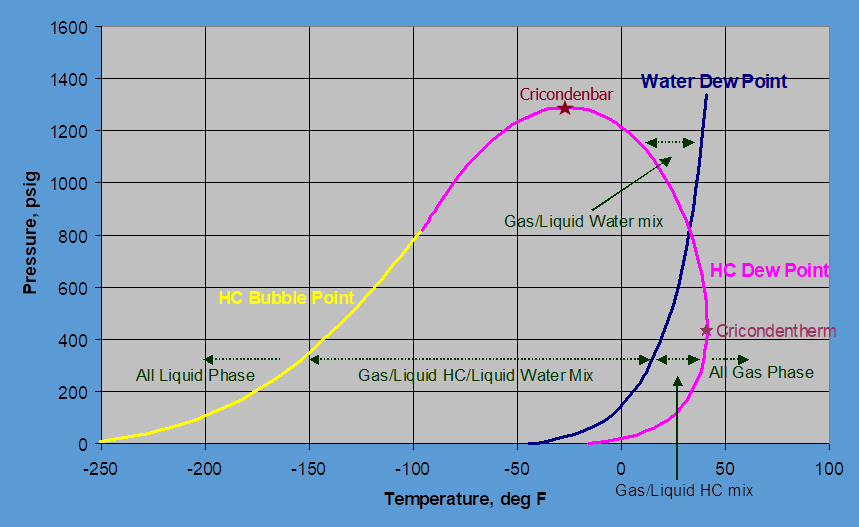

Hydrocarbon Dew Point (HCDP) indicates the temperature at which heavy hydrocarbon components begin to condense out of the gas phase when the gas is cooled at constant pressure. It is sometimes referred to as ‘droplet removal of liquid hydrocarbons’.

Therefore, a higher HCDP usually indicates a higher proportion of heavy hydrocarbon components. This is an important parameter for pipeline operators: if the natural gas contains a high proportion of heavy hydrocarbons, there is a greater risk of liquid condensate forming in the pipeline.

The HCDP is defined as the series of coincident pressure and temperature points at which hydrocarbons condense into liquid from a natural gas mixture. It is usually shown in a phase diagram (see below) as a function of gas pressure and temperature, for natural gas with a given composition. The dew point line divides the gas-liquid two-phase region and the gas one-phase region. Two dew point temperatures are possible at a given pressure and two dew point pressures are possible at a given temperature.

This phenomenon of the phase envelope gives rise to a behaviour known as retrograde condensation. The word ‘retrograde’ means that it moves backwards and this phenomenon received this name because it is contradictory to the phase behaviour of pure components, which condense when the pressure increases and/or the temperature decreases. The maximum pressure at which liquids can form is called cryocondensation, and the maximum temperature at which liquids can form is called cryothermy. Note that, given the shape of the phase envelope, the measurement of the dew point of hydrocarbons and the liquid potential of hydrocarbons is usually carried out at a pressure of between 25 and 30 bar (ideally 27 bar), where the liquid falls at the highest temperatures. When condensate is formed from a mixture of gases, the distribution of the hydrocarbons changes so that the liquid phase is enriched in the heavier components, while the gas phase is depleted of these heavier components. As the gas cools below its original dew point temperature, the entire dew point curve shifts towards colder temperatures for the remaining gas phase, which is now depleted in heavier components. The temperature of the cooled gas becomes the new HCDP of the gas stream.

Difficulties in measuring the dew point of hydrocarbons

The hydrocarbon dew point (HCDP) is not an easy parameter to measure. The composition of the gas, the contaminants and additives, the high pressures and the presence of corrosive compounds vary from one pipeline to another and they all affect the results of the measurements.

The HCDP is very sensitive to the specific components of the gas stream and is strongly influenced by the concentration of the heavier hydrocarbons, especially C6+. The presence of heavier hydrocarbons will increase the HCDP and not including them in an HCDP calculation will underestimate the HCDP. Therefore, an accurate determination of HCDP requires the evaluation of the distribution of the individual components in the C6+ fraction (at least C9 but possibly higher).

Cómo medir el punto de rocío de los hidrocarburos

There are several accepted methods for measuring the dew point of hydrocarbons that have been developed over time.

Online optical hydrocarbon dew point analysers

These analysers use a cooled mirror sensor to determine the dew point temperature of hydrocarbons in the gas sample accurately and automatically. Their main advantage is the reliable repeatability of the measurements: unlike the manual dew point analyser described below, the measurements are completely objective and automatic. Specialised operators are not required and the overall operating costs are low, although a significant capital investment is needed.

The Condumax CD603 dewpoint analyser from Michell Instruments uses the dark-point technique, which is a variation of the cold-mirror dewpoint sensor, to provide continuous and accurate HCDP measurements. Water dewpoint measurements are also available using the same analyser, utilising Michell's ceramic metal oxide humidity sensor.

Manual hydrocarbon dew point testers with refrigerated mirror

Designed to carry out spot checks of the quality of natural gas in pipelines and to verify the measurements of other hydrocarbon dew point analysers, hydrocarbon dew point testers are portable instruments designed to be easily used by a single engineer in the field. As well as their portability, the key advantage of the manual dew-point testers is their low capital investment. However, they are only recommended as a maintenance tool or to carry out spot checks at point where no online analyser is installed.

Despite their convenience, they have several disadvantages, including high operating costs. Although the instrument itself is simple, its use requires a lot of labour and highly qualified personnel. The measurements themselves are subjective, as they depend on the judgement of the operator. However experienced and well-trained the operators may be, the accuracy of the measurements will vary to some extent from one individual to another. Due to these factors, manual cooled mirror dew meters are only suitable for periodic gas quality checks.

The original technique for measuring the dew point of hydrocarbons was to use a refrigerated mirror hygrometer. This is a manual method that requires an expert operator to see the formation of condensation on a refrigerated mirror and use their judgement to determine the dew point temperature.

High-resolution video for reliable, repeatable measurements

Recent advances in new models of portable dew point testers have overcome many of the disadvantages and limitations of older instruments.

The Condumax CDP301 dew point meter from Michell Instrument uses the fundamental technique of the cooled mirror, but reduces the dependence on an operator's judgement to accurately record the dew point temperature. The CDP301 uses high definition video to show the formation of condensation on a screen, making it easier for users to determine the exact dew point temperature at the touch of a button. The video is also recorded to provide an accurate record of all measurements for later analysis. The CDP301 can also measure the dew point of water using the same cooled mirror sensor.

Gas chromatograph (GC) for an in-depth analysis of the composition of the gases

Used correctly, a gas chromatograph allows users to analyse the exact composition of their natural gas with greater precision. This method determines the concentrations of each hydrocarbon element (up to C12 in most cases). A gas chromatograph like the LDetek MultiDetek2-EX allows users to:

- combining a series of gas quality/tariff parameters in a single analyser

- identify the components that contribute to a high dew point level in order to determine the reason/source

- provide a theoretical phase envelope curve

Conclusion: What is the dew point of hydrocarbons and why is it important?

Understanding what the dew point is, specifically the hydrocarbon dew point, is crucial to maintaining the efficiency and safety of natural gas systems. The hydrocarbon dew point measures the temperature at which heavier hydrocarbons condense out of the gas phase, which can lead to operational problems such as equipment blockages and damage. Accurate monitoring and control of the hydrocarbon dew point helps to prevent these problems, ensuring the smooth and reliable operation of pipelines. The use of advanced measurement technologies makes it possible to accurately determine the hydrocarbon dew point, which is essential for optimising gas quality and safeguarding infrastructure.

Click here to find out more about our range of hydrocarbon dew-point analyzers.

Find more helpThe dew point of hydrocarbons and the processing of natural gas are complex issues. Please get in touch with us if you have any comments about this article or if you would like to discuss it further.

Related Products

Portable Dew-Point Tester – Michell CDP301

Condumax Dew-Point Analyzer – Michell CD603

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up