Nitrogen is one of the most common gases used in industry. It’s easy to produce large volumes of N2 from air using (vacuum) pressure swing absorption or membrane generators.

What are the main applications for nitrogen in hazardous areas?

Because nitrogen is an inert gas, it is often used to blanket or shield highly reactive chemicals from contact with the air or oxygen. This serves two purposes: product quality and safety.

The inert gas prevents unwanted oxidization within the process, which is essential for product quality. Flooding areas with nitrogen achieves safety by breaking the ‘fire triangle’. Increasing N2 reduces the amount of oxygen available – essentially removing one of the sides of the triangle.

An example of this is preparing a reactor vessel for routine maintenance. The vessel is emptied of the highly reactive chemicals, which leaves some residue as well as air. It is then flooded with nitrogen to the point where there is insufficient oxygen for a fire, referred to as the limiting oxygen concentration (LOC).

The LOC varies depending upon the gas, vapor, powder or hydrocarbon liquid or chemicals involved. The table below gives an example of limiting oxygen concentrations with nitrogen for flammable gases.

| Gas or Vapor | LOC in N2 or Air |

|---|---|

| Hydrogen | 5% |

| Methane | 12% |

| Ethane | 11% |

| Propane | 11.5% |

| m-Butane | 12% |

| Isobutane | 12% |

Generating nitrogen near the point of use is cost-effective and efficient

The main advantage of using nitrogen as an inert gas for hazardous processes is that operators can easily generate it on-site relatively cheaply. Membrane or (V)PSA nitrogen generators produce gaseous nitrogen from compressed air. They are compact, skid-mounted plant that can be supplied in an ISO container and easily installed close to the point of use. This eliminates the cost of transporting the gas. In the case of offshore installations, the cost and complexity of getting cylinders on board is great.

In most cases, the nitrogen generator is sited in a safe area, and the nitrogen generatesd is piped to the process in the hazardous area. Typical locations for nitrogen generators include:

- Off-shore platforms (operators usually install the generator on a skid or container and place it as far from the point of use as possible)

- Pharmaceutical plants

- Petrochemical refineries

What are the primary measurements for the quality and safety of nitrogen produced via pressure swing absorption or molecular sieves?

There are two critical measurements needed for ensuring the quality of nitrogen produced for use on-site: trace oxygen and, often, moisture. The diagram below shows the key measurement points for a typical Nitrogen generator:

Nitrogen generator measurement points

Oxygen: a (V)PSA Nitrogen generator will produce N2 at 97…99% purity, which means there is 1…3% O2 present and this is sufficient for most blanketing applications. Measuring oxygen at the point of production is essential to confirm the gas purity and ensure that the levels of O2 being piped directly into the hazardous process are well below the LOC. The analyzer is usually sited within the safe area.

Trace moisture: many applications need dry gases to prevent unwanted reactions with chemicals. If installed, trace moisture transmitters are placed at the air outlet from the compressor to ensure the air is dried sufficiently before being fed into the PSA nitrogen generator. Monitoring compressed air dryers in this way also helps to reduce and control money spent on the drying. Again this is usually sited within the safe area.

Measurements at point of use within the hazardous area

Oxygen: This is monitored to ensure that LOC is reached and maintained. Because the measurement point is directly in the hazardous area, an analyzer or sensor with a measurement point in the process – ensures the LOC (Limiting Oxygen concentration is reached.)

PST recommends: Reliable and low-maintenance Oxygen analysis suitable for hazardous areas

Michell XTP601 Oxygen Analyzer

PSA or membrane nitrogen generators are constructed on large skids for easy transport and installation in remote locations. An analyzer such as the Michell Instruments XTP601-EX1 Process Oxygen Analyzer is a good choice: it is fully approved for use in hazardous areas and has a ‘through the glass’ touch-screen interface, requiring no hot works permit. Especially important for remote locations, it needs minimal maintenance. Its thermo-paramagnetic sensor is non-depleting, and there are no moving parts to service.

It can be installed to monitor trace O2 at the generator measurement point or within the hazardous area to monitor N2 quality at the point of use.

The thermo-paramagnetis sensor has no consumable parts and offers calibration intervals of up to 6 months, making it ideal for remote locations. The analyzer offers a linear and stable measurement of oxygen air down to 100 ppm O2.

Ntron Minox-i Intrinsically Safe Oxygen Transmitter

Using electrochemical sensor technology, the Ntron Minox-i Oxygen Transmitter uses a solid-state sensor that measures 0…25 %O2 and has a long life of over five years. Not only reducing maintenance but also the cost of ownership. The transmitter is small and easily installed at the point of use to monitor the pure N2.

Ntron SIL-O2 SIL2-Rated Oxygen Analyzer

This is an analyzer and galvanic isolation barrier in one device. The control unit is sited in the safe area, and the sensor is installed at the point of use to monitor trace O2 in the N2 to confirm purity or ensure the LOC balance is maintained for process safety. It includes three configurable alarm outputs.

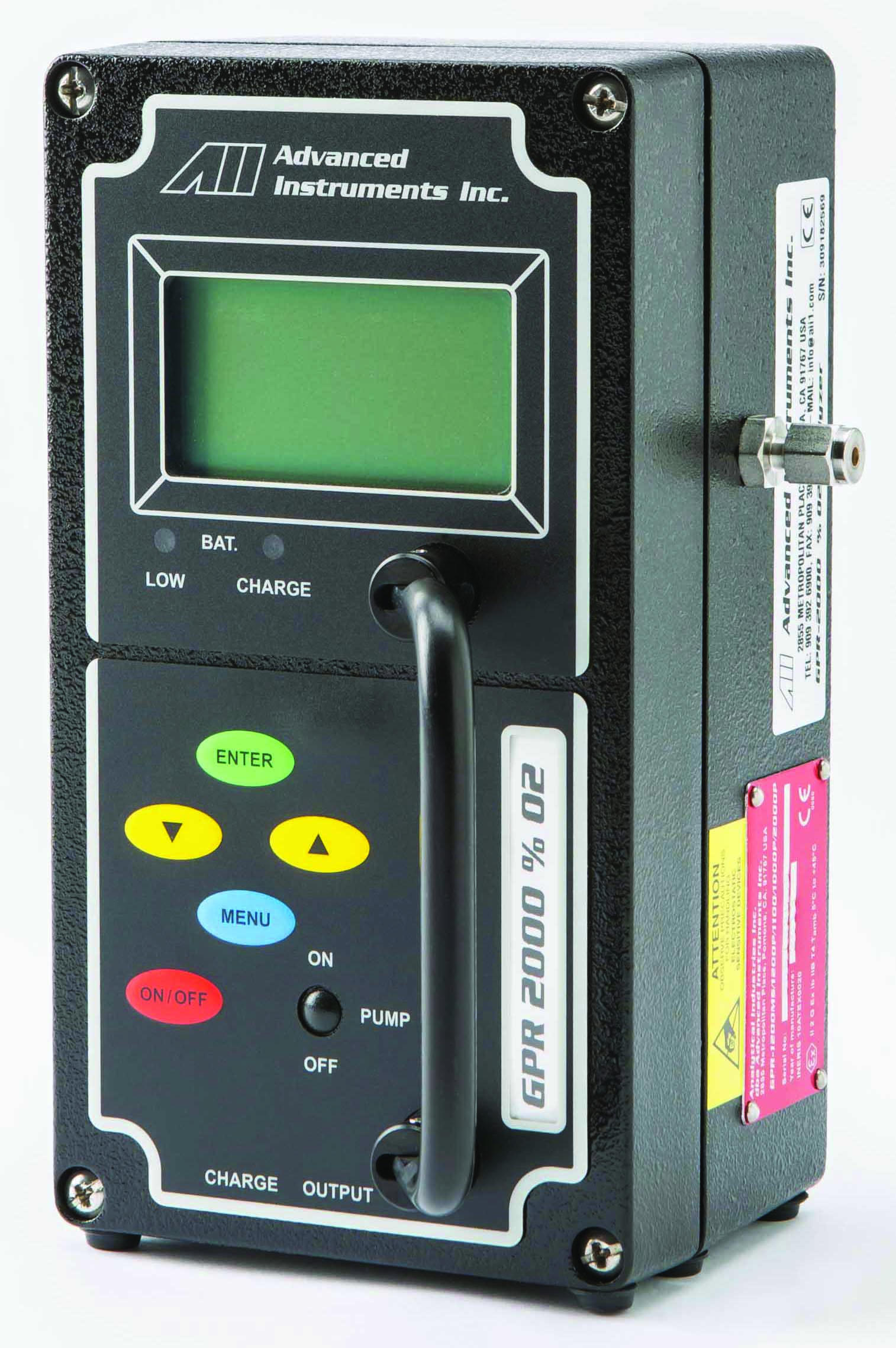

AII GPR-2000 ATEX portable oxygen analyzers for spot checks

These easy-to-use portable oxygen analyzers can be used in safe or hazardous areas to give reliable spot checks of trace oxygen levels to confirm nitrogen purity at the point of production and ensure the LOC is maintained at the point of use.

Ambient oxygen monitors ensure personnel safety

In hazardous areas the generators are in an enclosed safe area and if there is a gas leak, N2 levels in the area would rise and, eventually, there would be insufficient oxygen putting personnel at risk from hypoxia. Installing ambient oxygen analyzers – such as the Ntron Oxy-Tx or Dynament FGD10 - fixed gas detector, ensures alarms are sounded to alert staff of the danger.

Compact, rugged trace moisture transmitters for supplies of dry nitrogen

Within either the hazardous area or safe area, a dew-point transmitter such as the Michell Easidew PRO I.S. or Easidew PRO XP confirms the dryness of the air leaving the compressor or moisture content of the N2 at the point of use.

Need expert advice?

Contact us to to find out more.

Related Products

Transmitter for Moisture Analysis - Michell Easidew PRO I.S.

Explosion Proof Moisture Transmitter - Easidew PRO XP

Oxygen Analyzer - Michell XTP601

Compact SIL2 Capable Oxygen Analyzer - Ntron SIL-O2

Intrinsically Safe Compact Oxygen Transmitter - Minox-i

Portable Oxygen Analyzers - GPR-1100 and GPR-2000

Oxygen Analyzer for Hazardous Areas - Ntron OxyTx

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up