On-site gas generation offers a cost-effective, reliable, and safe alternative to liquid or cylinder supplies of oxygen or nitrogen. With the latest developments in pressure swing absorption (PSA) technology, on-site generation of high-quality oxygen and nitrogen is also possible. Process Sensing Technologies offers a suite of analyzers for PSA and membrane gas generators.

The gas generation industry is a fascinating and ever-changing business sector. In this blog post, we will look at some of the most important aspects of the gas generation industry and provide an overview of the current market landscape. We will also explore some of the key concerns facing customers within the industry and how PST’s suite of products can help solve these problems.

Application Outline

Ambient air contains 78% nitrogen, 20.9% oxygen, 0.9% Argon, 0.038% CO2 and other trace gases (Hydrogen, Neon, Helium, and others). Nitrogen and Oxygen can be generated from compressed dry air through 3 different methods:

1. Cryogenic

2. PSA (Pressure Swing Adsorption)

3. Membrane

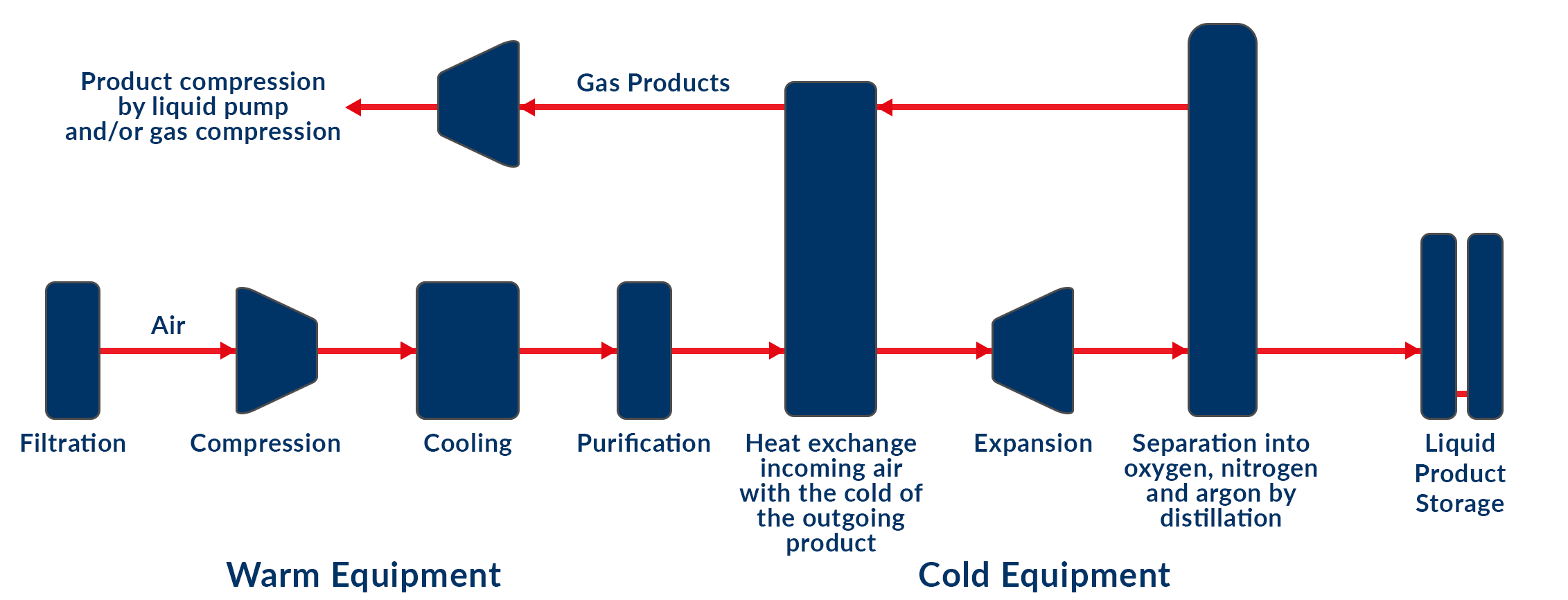

1. Cryogenic Gas Generation

It is estimated that 85% of the global supply of nitrogen is produced using cryogenic fractional distillation. Through cooling dry, clean compressed air to exceptionally low temperatures liquid nitrogen, oxygen and argon can be separated.

- Oxygen liquefies at -183°C / -297°F

- Argon liquefies at -186°C / -302°F

- Nitrogen liquefies at -196°C / -321°F

2. PSA Gas Generation

Pressure swing adsorption (PSA) technology enables Users to make the gas required themselves. PSA technology is more commonly seen in the drying of compressed air with desiccant dryers. By replacing the desiccant (molecular sieve) with Carbon Molecular Sieve Nitrogen can be generated or with Zeolite Molecular Sieve Oxygen can be generated. With the same twin tower design to compressed air dryers the sieve must be flushed / purged with treated gas to reactive the molecular sieve. This is referred to Nitrogen / Oxygen dependant switching.

Nitrogen generated using PSA technology is typically between 95% and 99.99% purity with the purity level being a function of the contact time within the sieve.

Oxygen generated using PSA technology is typically 95% purity. 99% purity can be achieved if the 95% purity is passed through a second stage.

A simplified operational diagram of the PSA gas separation process is shown below:

3. Membrane Gas Generation

Membrane gas generation uses a process called selective permeation to separate defined molecules from dry clean compressed air. The permeation is achieved though porous hollow fibres with different fibres having specific permeation capability to determine what gas passes through.

Nitrogen generated through Membrane technology has similar purity levels to the PSA process of between 95% and 99.9%.

Oxygen generated through Membrane PSA technology is typically around 95% purity.

A simplified operational diagram of the Membrane gas separation process is shown below:

PSA vs Membrane

- PSA is capable of higher purity levels flow rates

- PSA has lower operating costs

- Membrane has lower initial cost

- Membrane simpler to maintain – better for remote locations (marine applications)

Benefits of Gas Generation

- On demand production

- Independent operation

- Custom purity for each application

- Lower operating costs

- Eliminate losses associated with liquid evaporation

- Eliminate losses associated with unused cylinder balance

- No long-term contracts

- Reduced handling risks

Nitrogen Generation Industries and Applications

Beverage (coffee, wine, brewing, fresh produce)

| Application/Service |

|---|

| Processing Storage Bottling Carbonation |

Chemical and Refineries

| Application/Service |

|---|

| Blanketing Purging |

Electronics

| Application/Service |

|---|

| Reflow Soldering ovens Wave soldering Component cleaning and storage |

Fire Prevention Systems

| Application/Service |

|---|

| Inerting and purging – Oil and Gas / Chemical / Data banks |

Food

| Application/Service |

|---|

| Modified Atmosphere Packaging Fresh produce storage |

Metal Fabrication and Processing

| Application/Service |

|---|

| Plasma and Laser metal cutting Laser beam purge |

Pharmaceutical

| Application/Service |

|---|

| Blanketing / Purging - Product transfer/ Storage and Packaging Spray drying R&D – Glovebox / Isolation |

Semiconductor

| Application/Service |

|---|

| Inerting controlled environments Purging aggressive gas lines |

Steel Industry

| Application/Service |

|---|

| Heat treatment – Furnaces / Annealing / Sintering |

Oxygen Generation Industries and Applications

Aquaculture and Fish farming

| Application/Service |

|---|

| Improve oxygen in water for higher densities |

Brazing

| Application/Service |

|---|

| Furnaces / Torches – Increase temperature |

Breathing / Medical oxygen

| Application/Service |

|---|

| Reflow Soldering ovens Hospitals Breathing cylinders Enclosed spaces |

Glass blowing

| Application/Service |

|---|

| Ovens / torches - Increase temperature |

Gold mining

| Application/Service |

|---|

| Oxygen used in cyanide leaching process |

Pulp and Paper

| Application/Service |

|---|

| Delignification and other processes in manufacturing |

Sewage / Wastewater treatment

| Application/Service |

|---|

| Increase biodegradation rates |

Steel Industry

| Application/Service |

|---|

| Furnaces for decarburizing |

Other Opportunities in Gas Generation?

The cryogenic separation process can also produce the trace gases though distillation. 0.93% Argon is present in ambient air and is the third largest component. Argon can be generated with additional investment in plant and processing as by-product of the cryogenic separation process for Nitrogen and Oxygen.

The PST Group also has the ability to measure Argon purity using the LDetek MD3.

Gas Generation Customer key concerns

- Measurement accuracy

The instrumentation is often the only point of measurement for gas purity. Typically, the output of a SenzTx will feed a control system that will have alarm setpoints to control the as generation. Measurement accuracy will influence the performance of the generator. - Calibration Intervals

Calibration time = financial cost. Long calibration intervals are expected and calibration itself should be quick when performed. Typically, a zirconia sensor can have annual calibration / verification that is easy to perform. - Reliability

A generator is often located in a small, enclosed area within a building, and in a basement. The environment is quite harsh for instrumentation, hot and varying temperatures, electrically noisy and vibration may be an issue. The SenzTx has proven itself in these conditions for long term reliability and measurement performance.

Recommended Products

SenzTx Oxygen TransmitterThe SenzTx offers a true plug and play transmitter with no matching to monitors required. Can be specified with zirconia or electrochemical sensing technology –application dependent –and provided in ranges both in ppm and % oxygen.Easily integrated with gas flow though block and 4...20mA signal output. For those customers requiring digital communications RS485 is provided. NIST traceable calibration certificate provides confidence of calibration and as found / as left readings can be provided on recalibration. |

|

Microx Oxygen AnalyzerRemote sensor and monitor configuration that has electrochemical and zirconia measurement technology. The monitor has an LCD display and 3 configurable alarm contacts making it attractive to end users or integrators that are looking to provide a display of Oxygen without using the manufacturers HMI or control system. |

|

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up