Typical impurities in hydrogen

Since most hydrogen is generated via steam methane reforming, not surprisingly moisture is a major contaminant.

Steam reforming splits the methane into a mixture of hydrogen and carbon dioxide. Pressure swing absorption is used to remove most of the CO2, but it is not a perfect process and potential impurities that remain include trace methane, carbon dioxide and other hydrocarbons.

Hydrogen produced via electrolysis of water although cleaner is still not pure. As well as the presence of moisture, typical contaminants include trace gases such as oxygen, nitrogen, and argon.

Want to know more details of these processes? Read LDetek’s full application note Measurement of trace impurities in UHP hydrogen for fuel cells

Impurity analyzers and measurement points recommended for steam methane reforming process

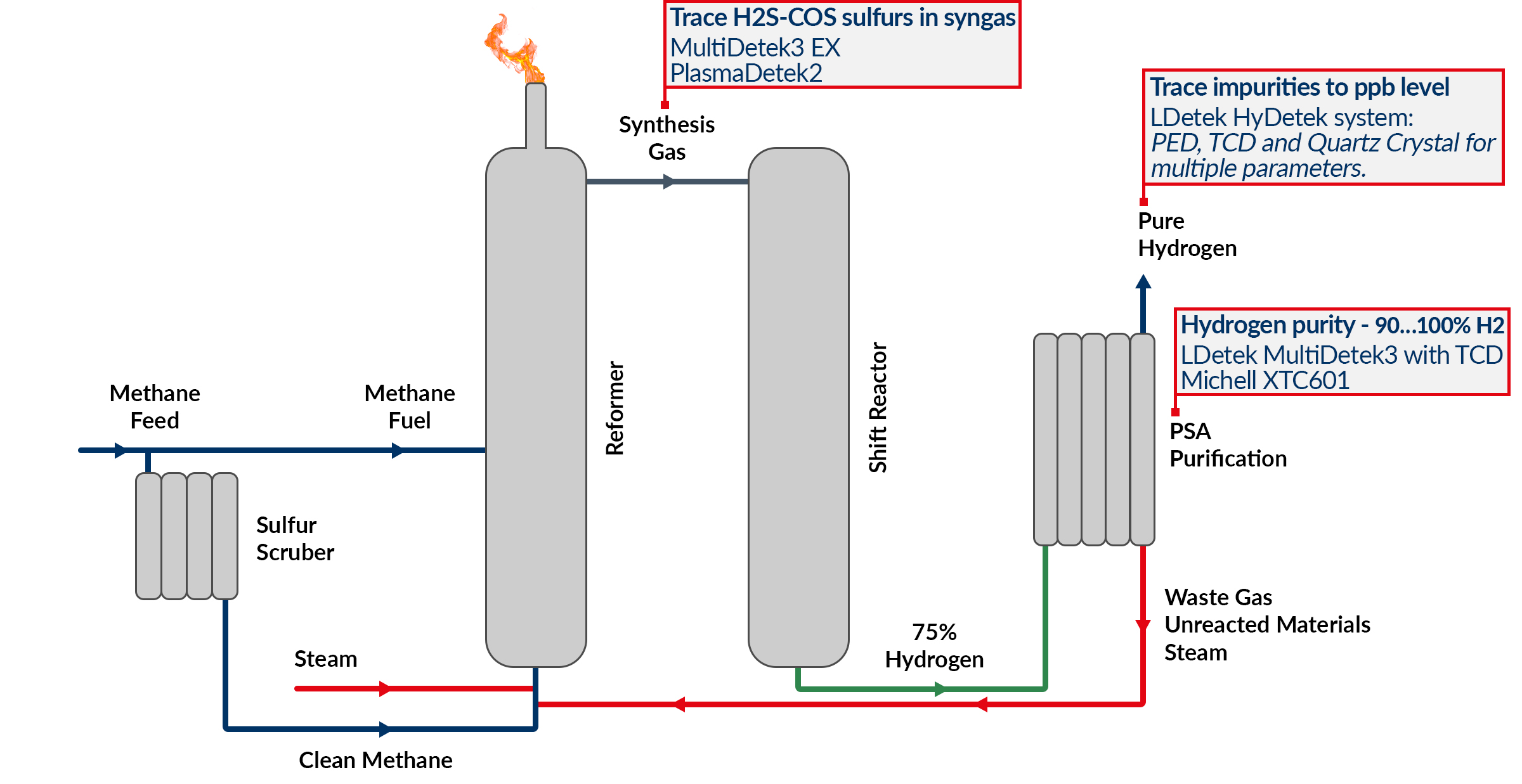

This simplified diagram of the process indicates the key measurement points in the steam methane reforming process.

Synthesis gas measuring point

The first stage of the process is to convert natural gas into syngas (a mixture of hydrogen and carbon dioxide). Because natural gas varies in composition, the first measurement point is to analyze the composition syngas with a gas chromatograph configured to selectively measure low ppm/ppb hydrogen sulfide and carbonyl sulfide in a background gas mixture of hydrogen, carbon dioxide and carbon monoxide.

Sulfurs are sticky so columns used must be coated with sulfinert – this enables measurement of trace sulfurs down to the low ppm/ppb levels.

We recommend the LDetek MultiDetek3 Gas Chromatograph, using the PlasmaDetek2 detector. It is possible to install the instrument directly in the hazardous area with the MultiDetek2 EX model. This is certified explosion proof.

Pressure swing absorption measuring point – hydrogen purity

After the PSA, a thermal conductivity analyzer set to 90-100% range measures the hydrogen purity.

For hydrogen up to 99.9% purity, we recommend the Michell XTC601 for this application. It is certified explosion-proof for use directly in the hazardous zone and has a small footprint for easy installation.

For UHP hydrogen, 99.99% purity and above, we recommend the LDetek MultiDetek3 with a thermal conductivity detector (TCD) set to the range 99 to 100% O2.

Pure hydrogen measurement point – trace impurity detection

A final measurement point confirms the quality of the hydrogen produced to determine the levels of individual trace impurities, including moisture.

We recommend the LDetek HyDetek System. This is an all-in-one solution developed specifically for hydrogen production. Using a combination of plasma emission detector, thermal conductivity and quartz crystal microbalance sensors, it monitors all potential contaminants in the hydrogen.

These include: N2, Ar, He, O2, CH4, CO, CO2, NMHC, sulfurs, formaldehyde, ammonia, halogenated formic acid and H2O.

Analyzers and measurement points recommended for hydrogen produced via electrolysis of water

This simplified diagram shows the key measurement points for impurities and hydrogen purity in the electrolysis of water.

Pure hydrogen measuring point

For an all-in-one solution, we recommend the LDetek HyDetek System. Pure hydrogen is measured using the TCD detector, configured to the 99-100% range.

Trace impurities such as argon, oxygen and nitrogen at sub-ppb levels are measured using a PED. Trace moisture measurements are made with a quartz crystal microbalance moisture sensor.

Alternatively, for non-UHP hydrogen production, a combination of the Michell XTC601 Binary Gas Analyzer and the Easidew PRO I.S Dew-Point Transmitter can be used to measure hydrogen purity and trace moisture respectively. This is an effective combination where 99.9% purity is acceptable, and a more cost-effective solution is needed.

Want to find out more?

View our complete range of Gas Chromatographs and Hydrogen and Binary Gas Analyzers here.

Please contact us with any questions or comments on this article.

Related Products

Transmitter for Moisture Analysis - Michell Easidew PRO I.S.

Binary Gas Analyzer for Hydrogen Monitoring - Michell XTC601

Plasma Emission Detector for GCs - LDetek PlasmaDetek 2

Quality and Safety Gas Analyzer for Hydrogen Electrolyzer

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up