Before researching all the sensor types that PST has to offer, it is important to look at the bigger picture and understand where and how the sensor will be used. This means looking at where the sensor is going to be mounted, the application requirements and environmental factors. These are explained below.

Mounting position: where the sensor is to be mounted can narrow the selection field, for example, is space a restrictive factor?

Application: where the sensor is to be used can narrow the selection field:

- Food or beverage application?

- Medical or chemical handling?

Environmental factors; the environment in which your sensor will be working has a direct bearing on the material type you should select. Fluid type and temperature are key factors; for example, is the liquid corrosive; high or low temperature? Following on from this, the next few steps is to narrow down the number of options available to you.

Step 1 - Sensor Material

|

It is important to consider what material is more than likely going to suit your mounting, application and environmental requirements. Does it have to withstand corrosive liquids, extreme pressure or temperatures?

Please note: when making your selection that the body of some of our fluid level sensors are made from a different material to the sensor tip. PST offers three housing material options depending on fluid sensor type: Polysulfone, Trogamid® (EU food-contact grade) or stainless steel. Again, depending on sensor type, PST offers three tip material options: Polysulfone, Trogamid® (EU food-contact grade) or glass. |

|

Step 2 - Sensor Types

This is the step where you look closely at the sensor specifications and make sure it is going to be suitable for your application environment. There are six fluid level switch ranges within the liquid level family: Optomax Digital, Optomax Industrial, Optomax Industrial Glass, LLHP, POS and Optomax Basic. The following gives a brief overview of each sensor and why they differ from each other based on operating voltage, temperature range and application.

Optomax Digital

|

The Optomax Digital Fluid Level Switch range is ideal for applications with restricted space that require a miniature, low power and low cost sensing solution.

|

Optomax Industrial

|

The Optomax Industrial fluid level switch range were designed to offer industrial supply voltages and outputs that can directly drive higher power loads.

|

Optomax Industrial Glass

|

The Optomax Industrial Glass fluid level switch range can operate in high pressure, high temperature aggressive environments due to their stainless steel and glass design, while offering industrial supply voltages and outputs that can directly drive loads.

|

LLHP (High Performance) Series

|

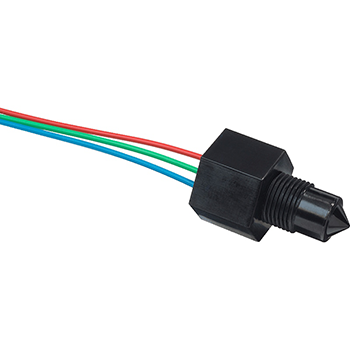

The LLHP fluid level switch range offer larger mounting threads and robust stainless steel housings that can survive in aggressive environments.

|

POS

|

The POS Glass Tip fluid level switch range is robust and rugged, ideal for operation in harsh industrial environments, aggressive chemicals and extreme temperatures up to 140⁰C.

|

Optomax Basic

|

The Optomax Basic fluid level switch range is an analogue optics only solution designed to meet the needs for price sensitive, high volume OEM applications.

|

Step 3 - Select and Test

Once you have narrowed your selection down to one or two products that may be of interest, PST recommend to test a sample of the product to ensure it will work in your application. We normally recommend testing the product, fully submersed in the liquid at maximum temperature for 2 weeks.

If at any point you are unsure of what fluid level sensor is going to be suitable for your application, our team of engineers provide full application and technical support on all of our products and would be happy to assist in choosing the right sensor that will meet your requirements.

Related Products

Cost-Effective Liquid Level Switch for OEM - SST Optomax Basic

Rugged Heavy Duty Liquid Level Switch - SST LLHT Series Glass Tip

High Performance Liquid Level Switch - SST LLHP-Range

Miniature Liquid Level Switches - SST Optomax Digital Range

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up