Dew-Point Sensor or Transmitter Calibration

The subject of dew-point sensor calibration may not set the pulses racing … but ignore it at your peril!

Every dew-point sensor is manufactured to the highest standards and tightest tolerances. In common with the majority of dew-point sensor manufacturers, we always supply a certificate of calibration with each new instrument. This is your guarantee that the product meets the stated specification and will perform as required from the outset.

It is important to recognize, however, that the operating characteristics of all mechanical and electronic devices used in manufacturing or process operations will change over time. This is especially true for sensors that are used in demanding applications, or that are exposed to aggressive or contaminating media.

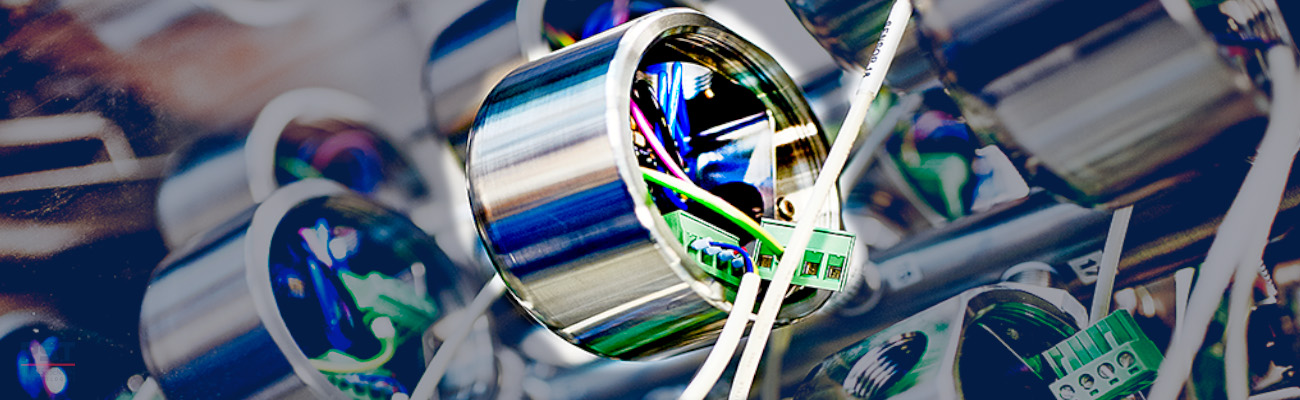

The latest ceramic metal oxide moisture sensors used in our Easidew range, for example, use an advanced three-layer structure, with a hygroscopic dielectric monolayer sandwiched between two charged outer layers of conductive metal. If a process gas such as compressed air is passed over the sensor, then the hygroscopic layer will absorb moisture, effectively changing the impedance of the current passing between the charged outer layers. The change in impedance is directly proportional to the concentration of moisture in the gas, enabling an extremely accurate measurement of the moisture content to be taken.

In aggressive applications, and over an extended time period, the accuracy of the sensor can become less stable. Although this may only be a small change, perhaps less than one percent, it may be sufficient in critical applications to cause a more significant change in process conditions. Even in less critical areas, such as the monitoring of dryer performance in compressed air systems, a slow change in sensor accuracy can lead to a deterioration in moisture measurement in the air.

How are dew-point sensors calibrated?

The calibration of dew-point sensors is carried out by comparing the parameters of each sensor against an approved reference instrument under laboratory conditions, to identify any bias or systematic error. For example, our Easidew moisture sensors are calibrated to measure dew point against advanced and extremely accurate chilled-mirror reference hygrometers. Each sensor is tested against a series of 13 dew-point temperatures across its measuring range, from -100 to +20 °C dew point, and a detailed Certificate of Calibration issued.

How often should dew-point sensors be calibrated?

The frequency of recalibration will vary depending on your particular application needs. Michell’s general recommendation is that dew-point transmitters should be checked once a year to ensure they continue to operate accurately. This normally requires each instrument to be returned to our UKAS approved laboratory, where we check for accuracy, recalibrate, service and return the product.

Sensor Service Exchange Programme

An alternative, and more popular, option is to subscribe to our Sensor Exchange Programme

Shortly before recalibration is due, you simply order an exchange sensor. This is swapped for the original instrument and the latter is returned to our laboratory to be refurbished, fitted with the latest updates, and recalibrated. Calibration data is stored within each exchange sensor, which is fully guaranteed and supplied with a detailed Calibration Certificate. This approach is simple, efficient and cost-effective, ensuring that your production line or process operation continues to operate smoothly, with a minimum of downtime.

To learn more about our dew-point sensor calibration and exchange services Click here.

Dew-point monitoring and traceability

A correctly maintained and calibrated dew-point sensor or transmitter is essential for optimum process or system performance and traceability. In most applications, a number of sensors will be installed permanently at key locations. It is also worth considering the use of a portable measuring instrument to carry out spot checks on parts of the process where fixed sensors are not used. This will help to confirm that sensors are operating correctly, identify possible issues elsewhere in the process and provide additional data for subsequent quality management and traceability procedures.

With over 45 years of experience in trace moisture measurement, Michell Instruments is the application expert when it comes to controlling moisture in compressed air and other process gases.

Contact us to discuss your application.

Learn more about our latest Easidew sensors here

You may also be interested in our blog on False Assumptions that Engineers still Believe about Metal-Oxide Moisture Sensors

Related Products

Compressed Gas Dew Point Meter - Easidew PDP

Dryer Portable

Dew-Point Transmitter - Michell Easidew EA2

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up