Measuring the dew point for nitrogen and oxygen in gas generators

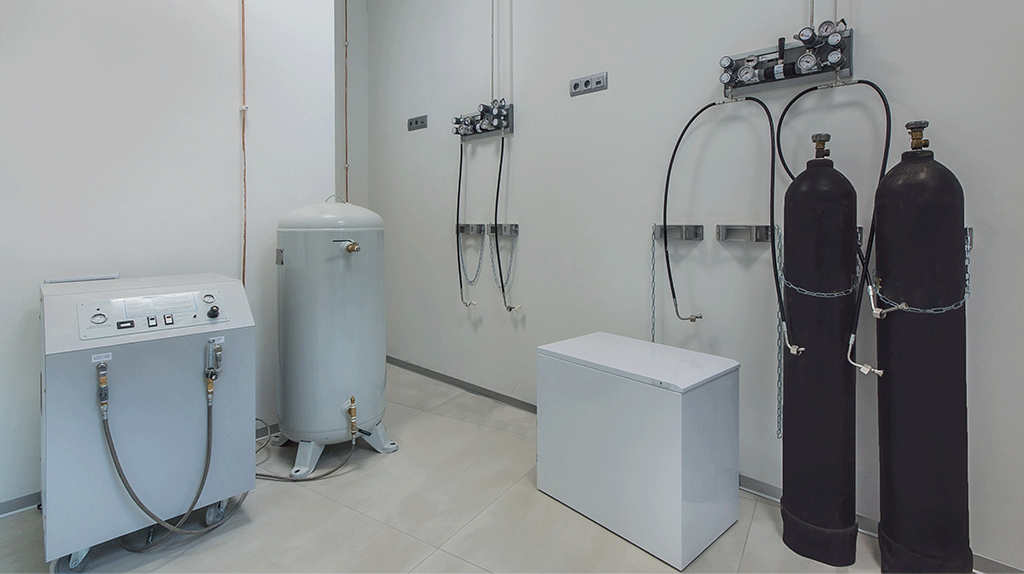

On-site industrial gas generator usage has grown considerably in recent years, not least for the production of oxygen and nitrogen. The latest generators can produce high volumes of gas at consistent levels of quality and pressure, meeting the demands of a wide range of industrial processes.

The considerable benefits to using industrial gas generators instead of traditional supplies to on-site silos include:

In many instances, the cost per unit of gas – both nitrogen and oxygen – can be considerably lower, especially once the capital cost of the generator has been written off.

However, these benefits only accrue if the gas generator is operating at optimum levels of efficiency and reliability, producing consistent gas purity.

The role of the dew-point measurement sensor

This is where the use of in-line nitrogen or oxygen dew-point measurement sensors, within the gas generator, play a crucial role.

Industrial nitrogen and oxygen gas generators use a compressed air feed. This either passes through a membrane filter to separate oxygen and nitrogen or, more commonly, a carbon molecular sieve (CMS) within a pressure swing absorption (PSA) system, which isolates the required molecules of gas. In each case, the pressurized air feed must be free of contaminants, including oil, particles and, most importantly, moisture. The performance of the compressed air dryer is therefore crucial to prevent condensate from damaging the CMS. This is because molecular sieves have a high affinity for moisture, which affects their ability to function correctly; it is both difficult and costly to remove or desorb.

A dew-point sensor on the inlet side of the generator enables air-feed quality to be monitored and, if a problem is detected, allows the air flow to be diverted then purged before the CMS becomes damaged.

The Easidew Dew-Point Transmitter is an ideal product for this application. It is a compact, precise and cost-effective device, capable of measuring pressure dew point from -110 to 20 °Cdp, with an accuracy to within ±2.0 °Cdp. It uses the latest ceramic metal-oxide moisture sensor technology, ensuring optimum stability and consistency over a long operating life.

In applications where comparable levels of moisture efficiency are crucial, it is important to note that dew-point sensors should be fitted both on the inlet side of the generator and the outlet feed, to measure the dew point of the generated nitrogen or oxygen gases.

Using oxygen sensors to elevate gas quality

For nitrogen and oxygen gas generators – especially the latter – the use of a SenzTX oxygen transmitter is imperative for ensuring high-output gas quality and system operating efficiency. Fitted to the outlet phase of the gas generator, the SenzTX uses a non-depleting zirconia electrolyte sensor mechanism to ensure fast response times with virtually no drift, and greater calibration intervals.

The market for on-site gas generation is steadily growing, while the use of high-purity nitrogen and oxygen is gradually being extended to a much wider range of critical applications. In this context, it is becoming ever more essential to use reliable dew-point and oxygen sensors to monitor generator performance, efficiency and output, for greater quality, safety and cost-efficiency.

With almost 50 years’ experience in the development of innovative precision sensors, we are the application experts in dew-point and gas measurements for all specialized gas applications. If you would like to discuss your requirements, please contact our team today.

To find out more about nitrogen gas in hazardous area applications, read our blog, Achieving Pure Nitrogen Production On-Site Safely for Hazardous Areas

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up