TDLAS technology and the measurement of trace moisture levels

In What is Tunable Diode Laser Absorption Spectroscopy? Part One, we introduced the concept of TDLAS, explained a little about its history and provided an overview of our latest OptiPEAK TDL600 trace moisture analyzer. In Part Two, we will dive a little deeper into how TDLAS technology works and take a look at how it can be used to detect water vapor in process gases.

TDLAS technology

Tunable Diode Laser Absorption Spectroscopy is, as the name implies, based on the principle of absorption spectroscopy. This is a widely used analytical technique that involves studying the way in which molecules in a sample gas react with light at different wavelengths, as it passes through or interacts with the sample. There are various measurement technologies used in absorption spectroscopy, including UV visible, nuclear magnetic resonance, X-ray, Raman and fluorescence spectroscopy. Each has its use in different applications.

The technology that has greatest relevance for the detection and measurement of specific molecules in gas samples is infrared spectroscopy. This is due to the nature of gas molecules, which constantly vibrate at specific frequencies, with a unique combination of resonance frequencies specific to each gas. Many of the gases of interest in industrial applications absorb light in the near infrared region of the electromagnetic spectrum, between the 2.5um and 750nm wavelengths.

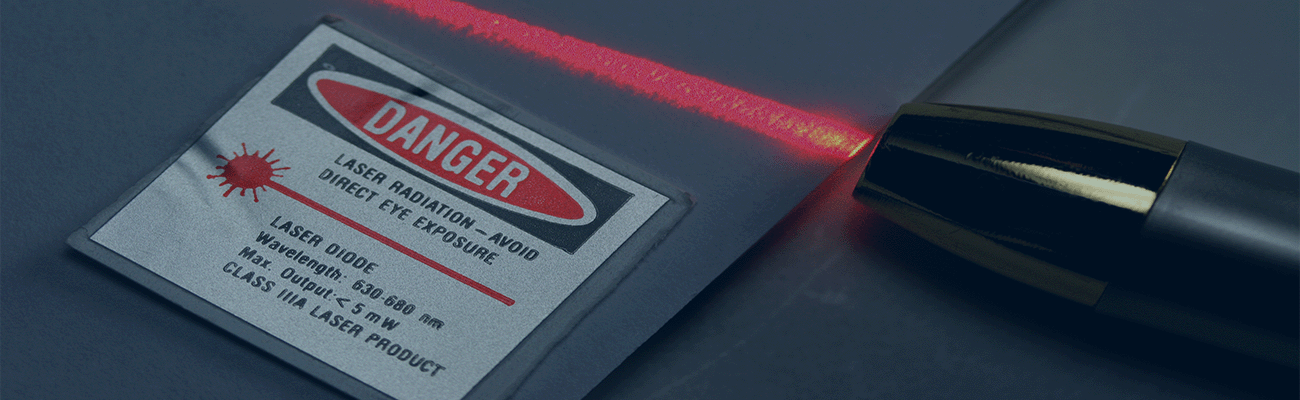

The light source in a TDLAS analyzer is provided by a tunable diode laser. This is designed to emit an extremely narrow beam of infrared light that can be tuned to specific wavelengths, which match the absorption wavelength of each target gas molecule. The wavelength of the laser is normally tuned by careful control of the operating temperature and drive current of the laser diode.

The gas sample is taken directly from the process operation and is fed to a sample cell or gas chamber, which has a set path length. This is an important measurement. When used with the absorption measurement and molar extinction coefficient (the way in which a substance absorbs light at a particular wavelength and concentration, defined by the Beer-Lambert law – see figure below), it allows the concentration of specific molecules in the sample to be calculated with high levels of accuracy.

In essence, the process is based on the characteristics of Infrared light. This is composed of photons, each of which has a resonant frequency. If the frequency of the photons matches that of the target gas molecules, they will interact and the energy from the photon will be absorbed by the gas. Conversely, if the frequencies are different, the photons of light will be rejected by the gas molecules and pass directly through the sample.

Light passing through the gas sample subsequently reaches a photo detector, where its intensity is measured. The output of the photo detector is then compared with that of the original output from the laser. These data sets are processed by the analyzer electronics to determine the absorption of the sample molecules at specific wavelengths, as well as their concentration within the sample. The presence of target molecules will show up in the resulting analysis as dark lines, or so-called absorption lines.

The unique properties of water vapor

By comparison with many gases, water has a more complex and non-linear molecule. This means it has three distinct vibration modes determined by the oxygen–hydrogen bonds: a symmetrical O-H stretch, an asymmetrical O-H stretch and a symmetrical O-H bend. This produces a complex but unambiguous absorption spectrum, with the precise locations of the absorption peaks within the infrared measurement spectrum being unique. This means that the laser analyzer can easily be tuned to one of these peaks to detect only the presence of water in the gas sample. The bandwidth of the laser is extremely narrow – typically 0.05nm – and the beam of light is set to scan across the area of the absorption spectrum where the water absorption peak occurs, to eliminate potential interference from any other gases present.

An exception is where concentrations of carbon dioxide are present, as the absorption spectra of CO2 and water vapor partially overlap. This can be especially problematic in applications such as moisture measurement in natural gas, and requires the use of specialized data analysis algorithms and analyzer calibration techniques.

In most instances, the concentration of water vapor in process gases is likely to be low, at what are normally called ‘trace levels’. Effective measurement therefore requires the use of extremely sensitive and advanced analysis instruments if precise, consistent and reliable results are to be achieved. Devices such as our OptiPEAK TDL600, for example, use the latest advances in TDL technology to achieve a sensitivity of just 1ppm, making them ideal for trace moisture measurement in demanding natural gas and methane applications.

With over 40 years’ experience in the development of innovative precision instruments, we are the application experts in humidity measurements for all industrial applications. If you would like to discuss your requirements, please contact our team today.

The Beer-Lambert Law is a fundamental principle of absorption spectroscopy. It quantitatively relates the concentration of molecules in a gas sample to the amount of light each group of gas molecules absorbs at a specific wavelength.

This is expressed as: A=εlc.

- A = absorbance

- ε = extinction coefficient

- l = sample cell pathlength

- c = gas concentration

What this law states is that if the sample cell path length (l) is known and you know the wavelength-dependent molar absorptivity of the water molecule (ε) (a constant that describes how strongly a particular gas absorbs light at a specific wavelength), if the absorbance of laser light by the water molecules is measured (A), then the water concentration (c) of the sample stream can be calculated. This gas law is the basis of all photometric gas absorption measurements.

Related Information

Use TDLAS Moisture Analyzers to Monitor Moisture in Stored Natural Gas.

Related Blogs

What is Tunable Diode Laser Absorption Spectroscopy (TDLAS)? Part One

Precise Measurement of Moisture in Natural Gas

How Novel Optical Moisture Detection can Reduce Risk and Save Costs in Natural Gas Storage

How to Make the Best Choice of Moisture Sensor for your Natural Gas Process

Some Engineers Still Believe these Three False Assumptions about Metal Oxide Moisture

Related Categories

Trace Moisture Analyzers for Natural Gas Quality and Petrochemical Applications

Related Products

Moisture in Natural Gas Analyzer - Michell OptiPEAK TDL600

Process Moisture Analyzer - Michell QMA601

Process Moisture Analyzer - Michell Promet EExd

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up