Let's do some fact checking

Metal oxide moisture transmitters have been in use since the 1960s. As with any technology, the manufacturing processes, materials and specifications have all improved and altered over the years. (Just think how much computers or car engines have progressed since then!)

Because of the long history, there are some false assumptions that deter some users from considering metal oxide moisture sensors. Often, they are encouraged to invest in a more costly but less effective sensing technology for their application. Modern metal oxide moisture transmitters are cost-effective as well as offering users excellent reliability and accuracy in many trace moisture measurement applications.

In this post, we examine three of the most common misperceptions and explain the facts in the light of modern moisture sensing developments.

False Assumption 1:

“Metal oxide moisture transmitters are not temperature compensated which makes their readings unreliable at changing ambient temperatures”

In fact, almost any sensor will react to ambient temperature changes, not just metal oxide sensors. However, all Michell Instruments’ ceramic metal oxide moisture sensors have a built-in temperature compensation to make sure the readings remain in specification regardless of external temperature variations.

Today all moisture measurement technologies – including quartz crystal microbalance (QCM) and tunable diode laser spectroscopy (TDLAS)– require a temperature-stabilized environment to provide reliable and accurate readings. This is why, in many process applications, the sensing elements for TDLAS and QCM moisture analyzers are located in heated ovens and often measure at elevated temperatures making these technologies more expensive and adding to maintenance intensity.

False Assumption 2:

“Metal oxide moisture sensors are slow to respond to moisture events”

In most industrial applications, moisture measurements are used to protect a process by alerting operators to sudden changes from dry to wet. With the correct sample system, a ceramic metal oxide dew-point transmitter provides an adequate speed of response to protect against moisture events at a fraction of the price of competing technologies.

How the technology works:

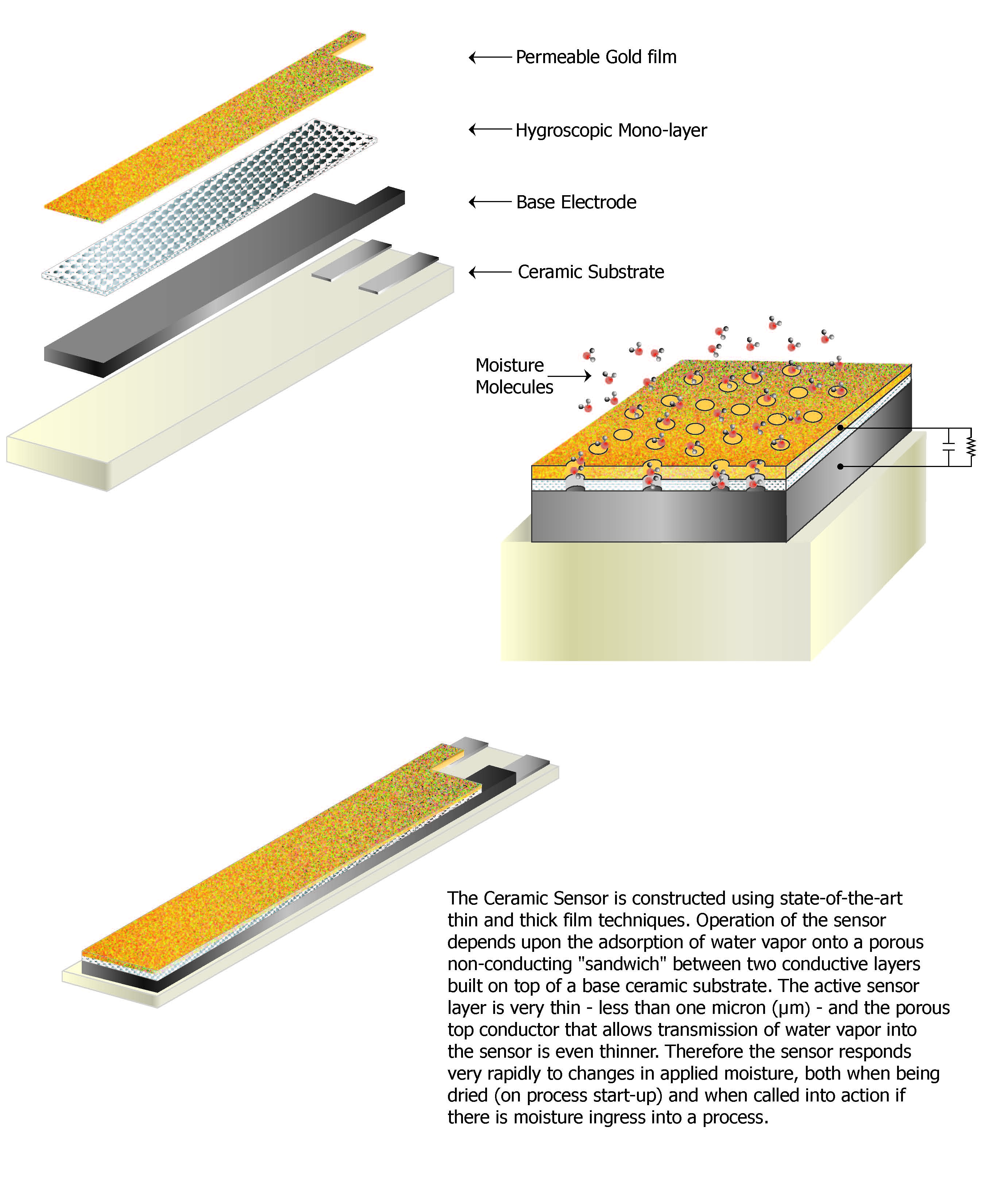

The Michell ceramic metal oxide sensor is made up of thin layers – less than one micron thick for the active layers – on a ceramic base. Water vapor is absorbed into a non-conductive layer which is sandwiched between two conductive layers. The sensor works by passing an electrical current through the conductive layers: when the sensor is totally dry, the current is stopped by the non-conducive central layer. As the moisture in this layer increases the current becomes stronger, and this is used to determine the amount of moisture in the sample gas.

Michell Ceramic Metal Oxide Sensor

False Assumption 3:

“Aluminum oxide sensors require a lot of expensive maintenance”

Any measurement equipment on a manufacturing process needs regular service and maintenance to ensure continued quality of the end product and is required anyway by the quality system of the plant. For some moisture technologies, service and maintenance may involve significant cost associated with bringing in specialist engineers or sending parts away for work.

While we recommend Michell Ceramic Metal Oxide sensors have an annual recalibration, checking the instrument performance is often a desired procedure in any well-maintained quality system. Recalibrating a Michell transmitter is simple and can be carried out by any competent local technician.

Our sensor exchange program ceramic metal oxide moisture sensors make maintenance and service even easier. Customers who embarked on the program practically obtain a life-long warranty for their transmitters.

In conclusion

Ceramic metal oxide moisture transmitters are a reliable, cost-effective solution for many process trace moisture measurement applications. At Process Sensing Technologies, we understand the importance of picking the right moisture measurement technology for your application, which is why we offer the largest choice of process moisture and humidity measurement technologies available from a single supplier. You can trust us to understand your application and help you find the best moisture sensor, analyzer or system for your needs. Why not get in touch today?

Related Products

Transmitter for Moisture Analysis - Michell Easidew PRO I.S.

Explosion Proof Moisture Transmitter - Easidew PRO XP

Dew-Point Transmitter - Michell Easidew EA2

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up