Rotronic meteo probes – vibration stable reference snow cannon

In a world struggling with challenges of climate change, Switzerland's enchanting Alpine regions have not been spared. The snow-capped peaks, synonymous with pristine winter landscapes and bustling tourism, now face a harsh reality. The iconic Swiss winters, known for their snowy charm, are slowly giving way to global warming and unpredictable weather patterns.

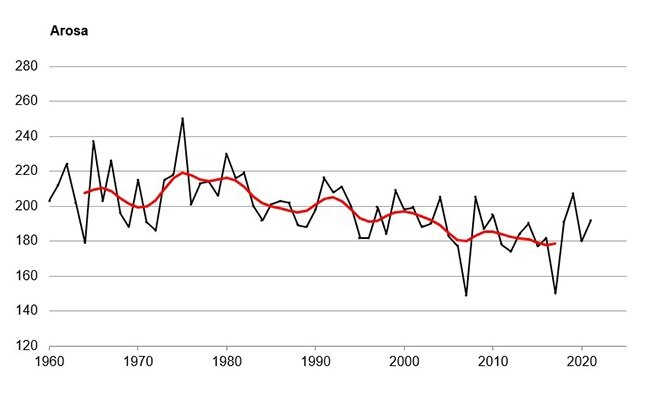

Due to the higher median-temperature in Switzerland, we face delayed build-up of snow cover and the earlier removal of snow cover with impressive consequences for the duration of snow cover periods. For example, Arosa, a well-known ski resort in Switzerland, the typical snow cover of at least 40 cm could previously be expected on average from the beginning of December until 10 May. Today, the average snow cover in Arosa is only at least 40 cm from mid-December to 20 April, a reduction from just under five and a half months to only four months:

This change not only threatens the stunning scenery and fragile ecosystems that rely on seasonal snowfall, but also jeopardies the thriving winter tourism that keeps many Swiss communities alive. Amidst this challenge, however, a remarkable innovation has emerged as a glimmer of hope:

Artifically produced real snow within Europe

To boost snow cover artificially, real snow production is possible and commonly used globally. The proportion of artificially snowed slopes in Switzerland can vary from year to year and from region to region. To ensure reliability and extend winter sports seasons many Swiss ski resorts invest significantly in snowmaking equipment. This is particularly important as Switzerland is heavily dependent on winter tourism. The exact proportion of artificially snowed slopes will depend on the weather conditions and the investments made by the ski resorts. Some sources estimate that around 30 to 40 % of the slopes in Switzerland can be artificially snowed.

The snow cannon

Snow cannons are the most common solution for localized artificial real snow production. The operation of a snow cannon, also known as a snow lance or snow gun, involves using water and compressed air to generate small water droplets that crystallize into snow at low temperatures.

Function principle of a snow cannon

The snow cannon is connected to a water source, such as a pond or water pipeline. Water is directed into the cannon.

Compressed AirSimultaneously, compressed air from a compressor is directed into the cannon. This pressure is necessary to atomize the water and transform it into fine droplets.

AtomizationInside the cannon, water and compressed air intersect. The compressed air breaks down the water into tiny droplets that suspend in the air.

Crystal FormationWhen these tiny water droplets are propellered into the cold air, they freeze due to the low temperature. This freezing process leads to the formation of snow crystals.

Spraying onto the SlopesThe resulting snow crystals are then sprayed from the cannon onto the ski slopes or trails. There, they fall to the ground and create snow cover.

This process enables ski resorts to produce artificial real snow and ensure snow cover, particularly in regions with unreliable natural snowfall. Artificial snowmaking is crucial for maintaining ski conditions and extending the skiing season, providing a consistent and enjoyable experience for winter sports enthusiasts.

Climatic conditions to create artificial snow

Today, snowmaking systems with nozzle technology are primarily used. Water is sprayed through nozzles into the air and forms water droplets. At the same time, a mixture of compressed air and water is sprayed through smaller nozzles. These microscopically small droplets immediately freeze into ice grains. The ice grains then serve as freezing nuclei for the larger water droplets. Thanks to the nucleation, it is possible to produce snow at a temperature of just below 0 °C (normally the water would only freeze below -7 °C). To meet the needs of maximum productivity, large propeller machines running on compressed air are mainly used. However, the power consumption of such machines is up to 20 kW per hour, which is huge for large ski resorts with about 1000 snow guns. This means that the potential for saving energy is great. Running snow cannons at the wrong conditions can waste energy or produce unsafe icy conditions.

Operating system for snow cannons

Before the snow cannons are distributed on the ski area, a mapping of the climatic conditions is made and the supply shafts for the water pipes are created. So, then the individual snow cannons are distributed in the area.

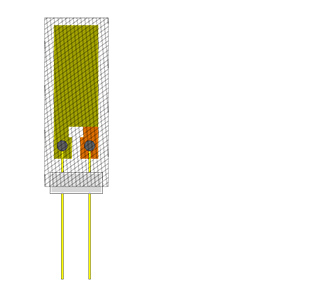

Vitally important are the temperature and humidity reference probes, which are installed outside of the snow cannon in a small weather shield. Measured data is transmitted to the main weather station. With additional software the individual snow cannons can be monitored and controlled to provide the best amount of snow.

Monitoring the Humidity and Temperature values is crucial for creating artificial snow and save energy resources, so that only artificial snow is created when the necessary conditions are present.

During the artificial snow production, there are increased vibrations, which can influence the reference sensor itself. With the introduction of our new HC2A generation, special care was taken to ensure that the sensor is vibration-resistant and the mechanical stability inside the sensing element is improved. Finally, the connecting legs of the sensor are provided with phosphor bronze covered with a gold layer, so that the Probe can withstand even the toughest environments. The HC2A range of humidity and temperature probes and their predecessors have been well proven in these applications over nearly 60 years. These probes have supported the production of snow to allow all winter sports enthusiasts to enjoy the widest possible winter season.

Related Content

Measuring Solutions for Meteorological Applications

Measurement Data is Critical for Accurate Weather Forecasting

The Importance of Humidity Measurement in Meteorology

Related Products

High-End Meteorological Probe - Rotronic HC2A-S3A

Meteorology RH and T Probes - Rotronic MP100A/MP400A

Meteo Transmitter for HC2A-S3 - Rotronic MP102H/402H

Weather Shields - Rotronic AC Series

RH and Temperature Probe Calibrator - Rotronic HygroGen 2

Meteo Humidity Probe - Rotronic HC2A-S3, S3H

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up