Belangrijkste kenmerken

- Suitable for use in ATEX, UKCA, IECEx, TR CU Ex & cQPSus certified Hazardous Areas

- Optional status LEDs following NAMUR standard

- Compact and rugged design with an EExd enclosure and 4...20 mA output

- Touch-screen display allows calibration or adjustment without the need for a hot works permit

- Accuracy of better than ±2 % full scale

- IP66 rated enclosure

- Low cost of ownership due to minimal maintenance

- Typical ranges available: 0...5 % up to 0...100 % (others gas dependent)

- Stability ±0.5 % per month (of range)

Overview

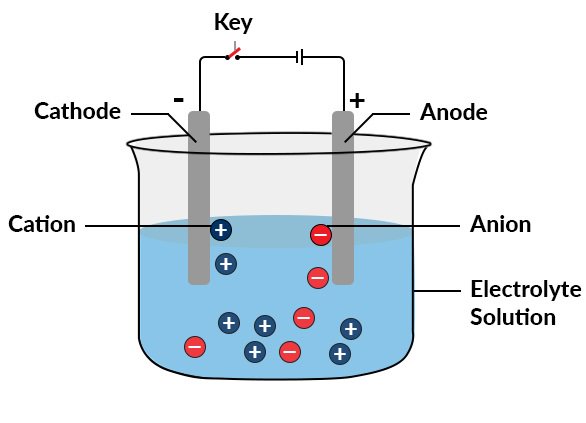

A robust, linear and stable thermal conductivity analyzer for measurement of binary gas mixes such as air in hydrogen, nitrogen, argon, helium or carbon-dioxide. The sensor is housed in a rugged casing, making it suitable for a wide range of applications. The analyzer can be supplied explosion-proof and suitable for hazardous areas.