Unlike moisture content (measured in parts per million) the water dew point temperature of a gas is a relationship between the moisture content, the temperature and pressure of the gas. Installing the dew-point transmitter correctly ensures that measurements are accurate and reliable.

There are two methods of measuring trace moisture in a sample gas with a dew-point transmitter:

In-situ measurements are made by placing the transmitter inside the environment to be measured.

Extractive measurements are made by installing the sensor into a block within a sample handling system and flowing the sample outside of the environment to be measured through this system.

Installing a dew-point transmitter to make in-situ measurements

Following these four points is essential to ensure the best accuracy and speed of response as well as protecting the sensor from damage.

Dew-Point Sensor Position – will the sensor see an area of the environment that is representative of what you want to measure?For example, if the sensor is to be mounted into a glovebox, there are three different positions shown in the diagram below in which it could be installed – each giving a different measurement:

Position A is on the purge inlet. In this position the sensor will confirm the dew point of the gas entering the glove box but will not detect any leaks in the glove box itself, or any moisture released from the work.

Position B is on the gas outlet. In this position the sensor will be exposed to the gas leaving the glove box and will detect moisture which has entered into the system through ingress or leaks as well as moisture that has been released by the work.

Position C is in the glovebox itself. In this position the sensor will be only detecting any moisture in its immediate vicinity. Leaks not close to the measurement point may not be detected as this moisture could be drawn directly to the outlet, by passing the sensor completely.

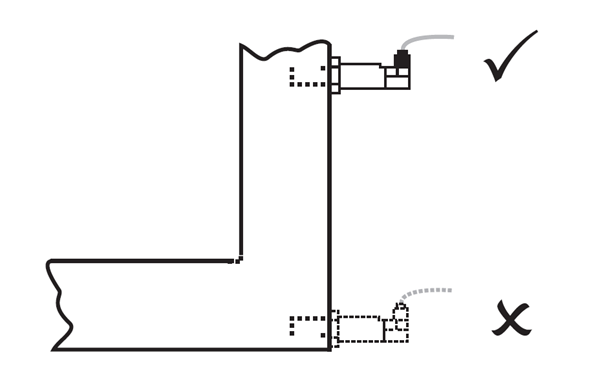

If the transmitter is to be mounted directly into a pipe or duct, then consider that the installation point should not be too close to the bottom of a bend where oil or other condensates may collect.

Using a dew-point transmitter to make extractive measurements

We recommend extractive measurements in situation with:

- Excessive flow rate

- Presence of particulates or entrained liquids

- Excessive sample temperatures

Any one of these conditions will make in-situ measurements unreliable and may damage the sensor.

When the sensor is mounted in a sample conditioning system, you should consider the extraction point carefully. Make sure that the chosen extraction point is representative of the process – for example that the sample is flowing past the extraction point and not being pulled from dead volume.

Positioning the sensor and choosing the correct sampling materials are also very important considerations.

Our blog post 8 common pitfalls in moisture measurements and how to avoid them looks in detail at what you need to consider when designing a trace moisture sampling systems.

Find further support

Measuring trace moisture accurately can be a complex topic. Please get in touch with us if you have any comments to make on this article or would like to get some advice for your application.

Related Products

Dew-Point Transmitter - Michell Easidew EA2

Dew-Point Transmitter for Compressed Air Dryers - SF82

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up