Dew Point definition – What is dew point?

Dew point or water dew point is the temperature at which air becomes saturated with moisture at any given pressure, resulting in dew, fog, or frost formation. It is a crucial indicator of humidity and plays a significant role in various applications, including oil and gas, weather forecasting, and daily life (at home).

According to the National Physical Laboratory (NPL), dewpoint is defined as:

‘The temperature at which dew, or condensation, forms as you cool a gas. Where the condensate is ice, this is known as the frost point.’

What are the factors influencing dew point?

It is important to note that condensation occurs when the humidity level is at saturation (i.e., 100% RH) and on a surface with a lower temperature than the dewpoint temperature. The formation of condensation depends on pressure and humidity levels in gas.

While the temperature does not directly affect the dew point, it impacts the relative humidity (rh%) and absolute humidity (Pv) of gas.

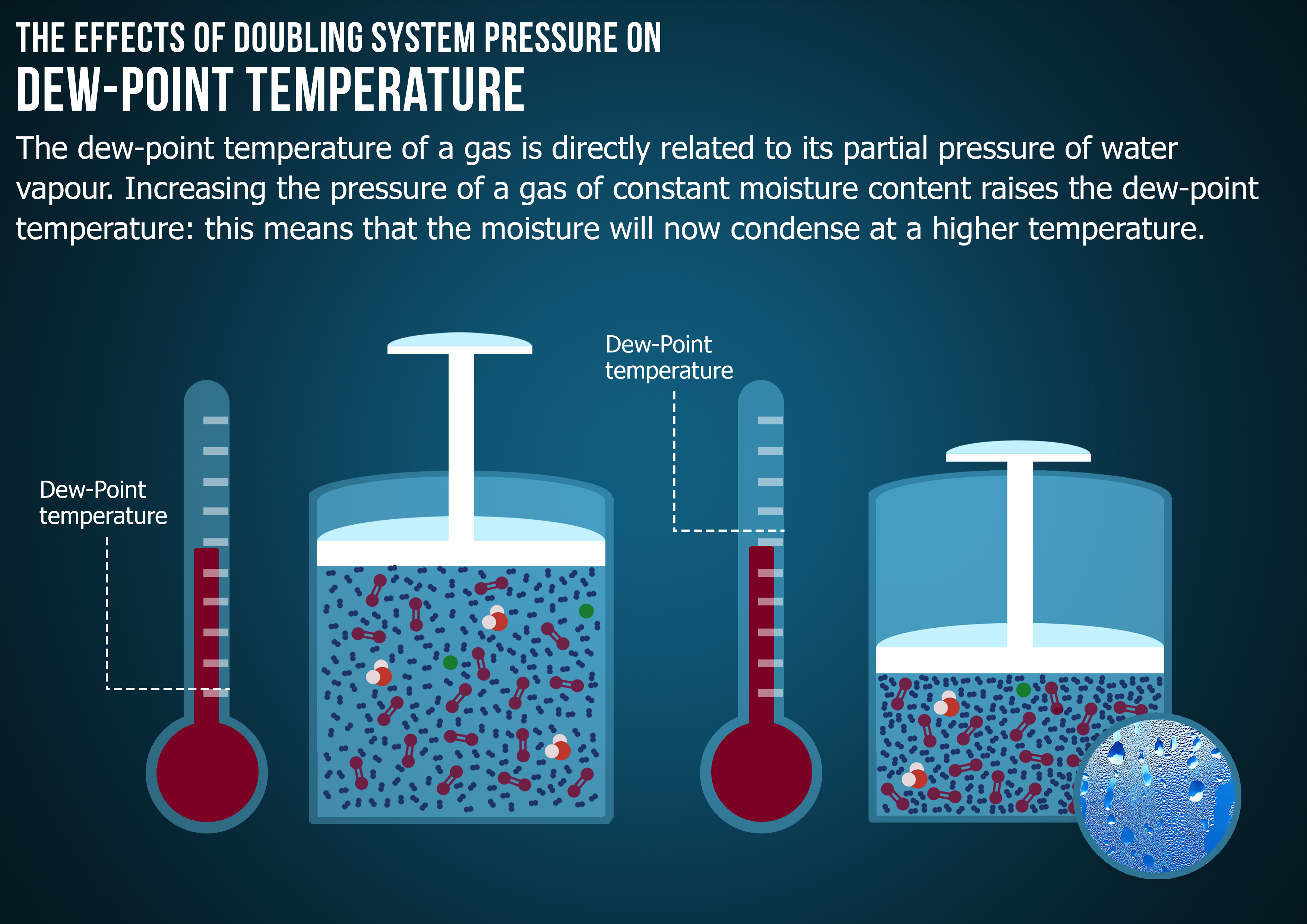

Pressure, however, is an important variable that determines dewpoint. It can affect dewpoint by influencing the air's capacity to hold water vapor.

When pressure increases, the gas molecules are compressed, and the gas becomes denser. In denser air or gas, water vapor molecules are more likely to collide with each other and condense into liquid water.

This means that, under low vapor pressure conditions, gas or air can hold more water vapor before reaching saturation at 100%. In comparison, higher vapor pressure conditions lead to the formation of frost.

A common principle when measuring dew point is that an increase in pressure generally raises the dew point, while a decrease in pressure lowers it.

An example to prove this known principle is seen in the graph below during a PST Michell Easidew Transmitter test.

Pressure increase from 0 brag increased to the expected dew point, and a decrease in pressure lowered the expected dew point. This directly proves the effect of pressure on dew-point using our Easidew Transmitter.

For pressure dewpoint conversations, download a copy of our free pressure dew point chart over ice and water.

Dew Point is a standard parameter in meteorology. However, in this article, we will look at why it is essential to a wide variety of industrial processes. (If you want to learn about meteorological applications for dew point measurements, here is a short explanation from the UK Met Office.)

Unlike other process variables such as temperature, pressure, and flow, moisture has two unique characteristics:

- It is difficult to measure accurately since moisture is directly affected by temperature and pressure.

- Process moisture is often a contaminant and can severely damage processes, equipment and reduce product quality.

This can be prevented with the use of a hygrometer.

What is hygrometry? – What is a hygrometer (dew point meter)?

Hygrometry is the measurement of the moisture content of gases, and a hygrometer senses, measures, and outputs or displays the relative or absolute humidity in the gas. As well as the term ‘hygrometer’ it may also be called a:

- Moisture analyzer

- Humidity sensor

- Dew-point meter

- Dew-point transmitter

- Dew-point monitor

- Moisture detector, etc.

PST brands Michell Instruments and Rotronic’s moisture and humidity measurement solutions are trusted by industry experts for dew point analysis.

What are the differences between humidity, dew point, and relative humidity?

Humidity is simply moisture that is dissolved in a gas or liquid. There is always a level of humidity in the air around us, but when it comes to industrial processes, the levels of humidity often need to be controlled.

Relative humidity is a measure of the humidity in terms of its saturation point. As with dissolving solids in a liquid, a gas can only hold a certain amount of dissolved moisture before it starts to condense back to the liquid phase. The saturation point varies depending on the temperature of the gas and the pressure, with higher temperatures and lower pressures allowing more moisture to be held in the gas as humidity. If the temperature is lowered or the pressure increases, the saturation point changes, and the %rh will also increase.

The %rh is a measure of how close to the saturation point the humidity in the gas is.

Moisture content is an important parameter for many processes too. Unlike relative humidity or dew point, moisture content doesn’t change with pressure or temperature: it’s a measure of the actual molecules of water in the gas.

It’s stated as parts per million by volume (PPMV)

Dew point is another variable measure of humidity. Instead of looking at the capacity of the gas to hold moisture, dew point measures the temperature at which liquid moisture will start to condense. As with relative humidity, the dew-point temperature is dependent on the pressure of the gas being measured.

It’s stated as °C dew point, °C frost point or °Ctd

Each of these parameters provide operators with a slightly different benefit. Because dew point is a measure of the temperature at which liquid moisture will condense, it is of most benefit in applications where operators need to avoid moisture condensing – for example in pipework where the ambient temperatures may drop to below freezing. Ensuring the dew point temperature of the gas is below the lowest possible ambient temperature means no liquid moisture will condense and there will be no risk of blockages due to ice.

Dew point is also a common parameter for monitoring the output of industrial dryers and may also be stipulated in quality regulations.

How to calculate dew point with water vapor equations?

The water vapor equation you will use depends on whether the dewpoint is above or below 0°C.

When dewpoint is over 0°C, the “over water” equation is used; likewise, if the temperature is less than 0°C, the water will condense straight to ice, meaning the “over ice” equation should be used. However, in some cases, a phenomenon known as supercooled water may occur.

Pitfalls to calculating dew point – Supercooled water phenomenon and how to solve it

In cases where the temperature is close but less than 0°C (I.e. -5°C), water can sometimes still exist as a liquid without transitioning to a solid (ice). This phenomenon is known as super cooled water. It can be problematic for calculating water vapor pressure as most calculators for water vapor will assume 'over ice' for sub-zero dewpoints. If the condensate is liquid, then the vapor pressure calculation would differ by around 10% compared to actual water vapor pressure, then the 'over water' equation should be used.

In industries like atmospheric metrology, since the super-cooling phenomenon can occur in clouds and the upper atmosphere, it was decided nearly half a century ago by the World Meteorological Organisation (WMO) that RH be calculated by computing the saturation water vapor pressure over water regardless of the temperature. This decision was to prevent the occasional possibility of %RH values exceeding 100% when the atmosphere was in a super-cooled state.

Measurement technologies like our chilled mirror (Michell S8000 and Optidew) get around this by further driving down the temperature to ensure the condensate is actually ice.

Dew-point water vapor equations

Some of the most used formulas for dew point calculations are Hyland and Wexler's (1983) and Sonntag's (1994) water vapor pressure formulas for industries.

See the equations below:

Hyland and Wexler's (1983) Vapor pressure equation over liquid water below 0OC

\( \ln(e_w) = -0.58002206 \times 10^4 / T + 0.13914993 \times 10^1 - 0.48640239 \times 10^{-1} T + 0.41764768 \times 10^{-4} T^2 - 0.14452093 \times 10^{-7} T^3 + 0.65459673 \times 10^1 \times \ln(T) \)

Where:

- \( \ln(e_w) \) is the natural logarithm of vapor pressure over liquid water (Pa).

- \( T \) is the temperature in Kelvin (K).

Sonntag's (1994) Vapor pressure equation over liquid water below 0°C

\( \ln(e_w) = -\frac{6096.9385}{T} + 16.635794 - 2.711193 \times 10^{-2} T + 1.673952 \times 10^{-5} T^2 + 2.433502 \times \ln(T) \)

Where:

- \( \ln(e_w) \) is the natural logarithm of vapor pressure over liquid water (hPa).

- \( T \) is the temperature in Kelvin (K).

Hyland and Wexler's (1983) Vapor pressure equation over vapor pressure over ice

Hyland and Wexler (Hyland and Wexler, 1983.):

Log ei = -0.56745359 × 104 / T

+ 0.63925247 × 101

- 0.96778430 × 10-2 T

+ 0.62215701 × 10-6 T2

+ 0.20747825 × 10-8 T3

- 0.94840240 × 10-12 T4

+ 0.41635019 × 101 Log(T)

with T in [K] and ei in [Pa]

Source: Water Vapor Pressure Formulations (colorado.edu)

Sonntag's (1994) over vapor pressure over ice

Sonntag, (1994)

Log ei = -6024.5282 / T

+ 24.721994

+ 1.0613868 × 10-2 * T

- 1.3198825 × 10-5 * T2

- 0.49382577 * Log(T)

with T in [K] and ei in [hPa]

Source: Water Vapor Pressure Formulations (colorado.edu)

You can find more water vapor equations here: Water Vapor Pressure Formulations (colorado.edu)

For industrial applications, both formulas differ in their applicable temperature ranges. The Hyland-Wexler formula is effective within the temperature range of -100°C to 0°C, whereas the Sonntag formula is applicable within the broader range of -80°C to +50°C. This indicates that the Sonntag formula is more versatile, making it suitable for various applications.

Measurement of dew point and other humidity parameters are paramount for many applications. You can use our free humidity and dew point calculator for easy humidity conversions and calculations.

What industries measure dew point and why?

Dew point is slightly measured in several ways for different applications, but it is ultimately used to control moisture in a specific environment. Homeowners may measure dew point to control water vapor that leads to mold formation or to determine what humidity levels are most comfortable for humans.

Typical dew point measurement range

According to the National weather service, dew point is a good parameter to tell how dry or humid air is. If the dew point is less than or equal to 55 degree, air should be dry enough and comfortable for humans, between 55 and 65 dew point the air becomes sticky, while dew point greater than or equal to 65 tends to hold more moisture in air.

For industries, there is a need for even more dry air or control of moisture for industrial applications to meet standards, improve process performance, or maintain the quality of products.

In compressed air applications, it's important to continuously monitor compressed air systems to comply with ISO standards that specify permissible levels of solid particles, oil, and moisture.

The table below shows the compressed air purity (quality) classes for humidity according to BCAS

| Class | Vapour Pressure Dewpoint oC | Liquid g/m3 |

|---|---|---|

| 0 | As specified by the equipment user and more stringent than class 1 | |

| 1 | ≤ -70 | - |

| 2 | ≤ -40 | - |

| 3 | ≤ -20 | - |

| 4 | ≤ +3 | - |

| 5 | ≤ +7 | - |

| 6 | ≤ +10 | - |

| 7 | - | ≤ 0.5 |

| 7 | - | ≤ 0.5 - 5 |

| 9 | - | - 10 |

| x | - | > 10 |

Another example is natural gas and hydrocarbon applications, where trace moisture can lead to pipeline rust and the formation of hydrates that may affect the process's (gas flow) or the final product's quality.

Corrosion-resistant coatings can help avoid the formation of rust in pipelines.

However, it is not a lasting solution due to other factors such as aging and wearing, pipeline edges and joints, and environmental conditions such as extreme temperatures, exposure to chemicals, or high humidity, can affect the durability of the coating.

Aside the formation of rust, when water saturation occurs in natural gas pipelines, it forms hydrates (as seen in the image above), which may block the gas flow in the pipeline.

Experts across different industries use PST Michell dew point hygrometers and portable dew point meters to control moisture in their process.

What is the best way to measure dew point in an industrial process?

There are many options available to operators to measure dew point in industrial processes - the final choice depends on the specific application and often budget:

Dew-Point Transmitters are small and cost-effective and suited to a wide range of safe and hazardous applications.

Portable Dew-Point Hygrometers (Dew Point meters) are most suited for test and verification purposes. They can be used to check the readings of online moisture analyzers and also to make spot checks at different points in a process, for example to identify the location of leaks.

Process Moisture Analyzers are often, but not always, hazardous area-approved systems that include sample processing and a moisture analyzer. These are often designed for use in refineries or natural gas processing plants.

Chilled Mirror Hygrometers measure the actual formation of condensate on a temperature-controlled surface. They offer excellent accuracy with very little drift – although often used as laboratory references, many models are suitable for monitoring industrial processes such as semiconductor manufacture or metallurgical processes.

What are the benefits of measuring dew point in a process?

Moisture can penetrate virtually any surface, render test results useless, result in poor product quality, cause corrosion in tubing, lead to ice formation at low temperatures, cause premature wear and tear and equipment failure as well as react with other chemicals and gases.

Monitoring the dew point in a process gas gives the following benefits:

Process safety and protecting equipment

Excess moisture in pipework may cause corrosion and reduce the integrity of the equipment and possible leaks, or even explosions. In cold conditions, ice may form and block pipes. Controlling moisture reduces the need for unscheduled maintenance and protects staff.

Quality

Moisture has a detrimental effect on many final products. In metallurgy, the level of moisture in a furnace needs careful control to prevent weak products, whereas in pharmaceutical production powders must be kept dry to avoid clumping. Low moisture in necessary in refineries to avoid unwanted chemical reactions.

Saving Energy

The highest cost for many processes is the heat needed for dryers. Monitoring the output of dryers ensures that the cycle can be stopped as soon as the drying cycle in complete.

Meeting regulations

Many global industrial bodies agree international standards for quality, which often include moisture or dew point levels. An example of this is the EASEE gas standards for natural gas quality.

Expert advice for your application

Need advice on your trace moisture or humidity measurement application? Contact us with your question.

If you found this blog post useful, sign up to receive one of our monthly industry newsletters.

Related Articles

How to calculate Pressure Dew Points Accurately

Pressure Dew Point Chart (Conversion Tables)

Using a Chilled Mirror Hygrometer for Industrial RH Measurements

Related Products

Bluetooth Water Activity Measurement Head - Rotronic AwEasy

Bluetooth Water Activity Measurement Head - Rotronic AwEasy

Dew-Point Transmitter - Michell Easidew EA2

Compressed Gas Dew Point Meter - Easidew PDP

Dryer Portable

RH and Temperature Probe Calibrator - Rotronic HygroGen 2

Portable Dew-Point Hygrometer - Michell MDM300 Series

Industrial Grade Chilled Mirror Hygrometer - Michell Optidew

Portable Dew-Point Tester – Michell CDP301

Explosion Proof Moisture Transmitter - Easidew PRO XP

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up